BOXER 24 INJECTION is a pneumatic double diaphragm pump built for injecting all low/medium viscosity liquid products.

The direct suction from the source container ensures constant supplying.

All parts in contact with the product are made of a special acid-resistant and flame-retardant material.

No oil need neither special maintenance.

High reliability.

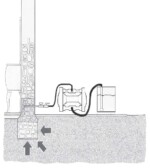

RISING DAMP

SYMPTOMS:

Rising damp can affect the totality of buildings with more than thirty years and it is manifested by:

– Mold stains at the base

– Plaster peeling

– condensation phenomena in rooms

CAUSE:

Rising damp is due to the presence of underground water and to the construction material’s ability to absorb this water.

REMEDY:

W.I.T. SRL has realized an injection system which, penetrating into the wall, forming a horizontal chemical barrier and prevents capillary rising humidity, drying the environment with immediate benefits for those who live in. Also it gets rid of any mildew stains, tit hermally isolates the wall and allow the restoration of plaster paintings. Inoltre fa sparire eventuali macchie di muffa, isola termicamente il muro e permette il ripristino di intonaci pitture.

General features

Diaphragm pumps offer significant advantages over other types of pumps, such as the absence of mechanical seals and / or gaskets that are often responsible for the pump breaking under tough working conditions. These pumps are self-priming, so it is not necessary to fill the fluid suction column to operate and can be used to aspirate liquid deposits, initially having suction pipe full of air.

Maintenance is fast and simple and it’s easy to replace components, which makes this type of pump equipment with a very low operating cost. Diaphragm pumps are very versatile: different set-up are available depending on the working temperatures and fluid to aspire. The most commonly used materials are neoprene, Viton, Teflon, polyurethane and other synthetic materials.

The high resistance to corrosion and the fact that they do not need to be primed to operate make these pumps widely used in industry for moving almost any liquid (acids, paints, construction, solvents, ceramic industries, chemical industries, food, paints, inks …).

Compression ratio: 1:1

MAX pressure: 8 bar

MAX inlet air pressure: 8 bar

MAX flow rate: 24 l/m