Pneumatic electrostatic unit with integrated airless generator W-MIX for solvent products complete with gun, W 12000 PLUS stainless airless pump and flat w.t. nozzle.

The electrostatic liquid painting is the ideal solution to many problems encountered in traditional painting. In particular, with this technology, it is possible to eliminate problems such as the orange peel effect and the dripping as it is possible to obtain significant savings in the consumption of paints, a significant decrease in over spray with consequent savings on the filters of the extraction plants and above all a quality of the highest quality paintings. But what are the differences between a traditional spray painting and an electrostatic painting? To better understand the differences it is necessary to know that each object to be painted has its own electrostatic charge. This electrostatic charge is concentrated in the corners and corners of objects and is smaller in regular surfaces. This phenomenon is due to the effects of the Faraday cage. In traditional spray painting in the points with a higher charge, more paint will be deposited creating problems of dripping and orange peel. As a result, even the thickness of the paint will be greater near the corners and edges and lower in the regular surfaces. The principle on which the electrostatic painting is based is that according to which “electrostatic charges of opposite sign are attracted and electrostatic charges of equal sign repel”. If particles of paint are charged through electrodes of negative electrical charges while the object to be painted is charged (simply with a grounding) of positive electric charges. The object to be varnished loaded with positive charges will attract the paint particles loaded with negative charges. Once the paint settles on the nearest part (corners and edges), the electrostatic charge in those points decreases and the paint particles will be deposited where, on the contrary, there is a higher charge difference. The effect will be to have a thickness of the homogeneous paint product ensuring a high quality painting. For the same phenomenon will be significantly reduced dripping and imperfections orange peel. Further benefit is that, by depositing on the object the greater quantity of paint, the quantity of paint necessary to obtain the same result with a traditional spray painting is considerably reduced (20% – 30%). Consequently, the over spray values will also be significantly lower with great benefits for the environment and with a reduction in the filters of the air extraction and purification systems.

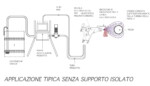

By using a water-soluble paint, with an almost zero degree of resistivity, it is necessary to completely isolate the feeding system to ensure a good electrostatic effect. Therefore, small insulated cabinets are proposed, with or without wheels, for small-scale applications or systems with power stations on isolated benches protected by a protective fence; both free of wear and maintenance. Vengono perciò proposti piccoli armadi isolati, con o senza ruote, per applicazioni di piccole entità oppure impianti con centrali di alimentazione su banchi isolati protetti da recinzione di protezione; entrambi esenti da usura e manutenzioni.

The advantages of electrostatic painting with electrostatic powder and liquid guns:

•Paint savings of around 30-60%.

•Quality result.

•Labor savings.

•Uniform paint layer, absence of dripping and orange peel effects:

•Penetration of the paint even in the most difficult areas.

Good corrosion resistance.

Content environmental impact.

Using water-soluble paints, the aforementioned advantages are also added that of seeing the costs of disposal of harmful substances reduced; the use of electrostatic technology, in addition to rationalizing the consumption of paint, allows industries to automate processes, to the benefit of productivity and quality.

It is estimated that with an electrostatic system there is a saving of paint from 20% up to 50-60%.

Compression ratio: 40:1

MAX pressure: 320 bar

Pipe elevation MAX: 100 m

Suggested MAX viscosity: 50,000 cps

Stroke volume: 73 cc

Voltage: up to 100 kV

MAX inlet air pressure: 8 bar

MAX flow rate: 15 l/m

MAX nozzle size: 0.053″

Hose length MAX: 100 m

Gasket pack: mobile

Cylinder diameter: 160 cm